Blasting and Painting

One of the most common ways of preventing corrosion to steel surfaces is to apply protective coatings. The coatings we apply may be an inhibitive, barrier, or sacrificial. The other reason for painting is for decoration, to provide markings or identification.

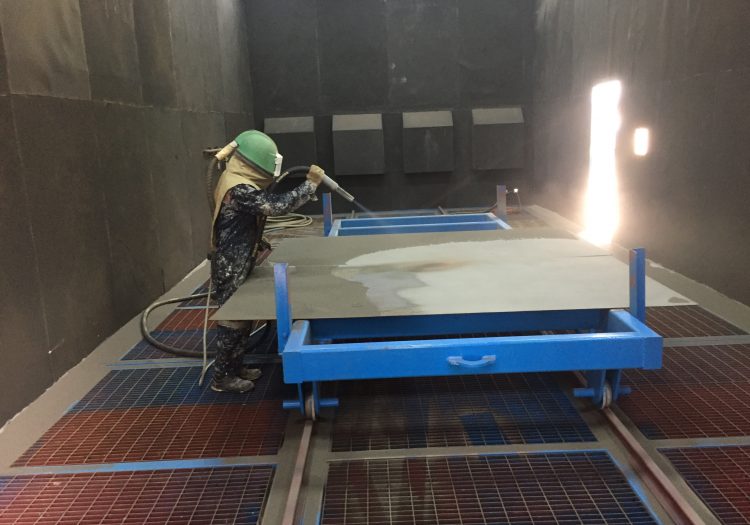

Abrasive blasting more commonly known as Sandblasting, is the operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface, roughen a smooth surface, shape a surface or remove surface contaminants prior to the protective coating.

Type of Abrasive Blasting Method – Dry Abrasive Method and Wet Abrasive Method

Type of Abrasive Materials – Copper Slag, Steel Grit, Garnet, and Sand.

The Purpose of Surface Preparation – is to clean and to roughen the substrate according to the requirements of the Specification.